Advanced Products Testing Solutions for Reliable Results

In the realm of materials screening, accuracy and precision are of utmost significance. With the ever-increasing complexity of advanced products, it is vital to rely upon trustworthy and robust screening options. This is where sophisticated materials testing options enter play. These options use advanced techniques and modern analytical instruments to ensure comprehensive and exact outcomes.

Non-destructive screening techniques allow for complete evaluation of materials without jeopardizing their honesty. Advanced logical instruments supply useful understandings into the buildings and actions of products at a tiny degree. High-temperature testing remedies allow the analysis of materials' efficiency under extreme conditions.

Furthermore, progressed mechanical testing techniques supply a deeper understanding of the mechanical buildings of products. Personalized testing options deal with particular demands and obstacles of different sectors.

By using these advanced products examining services, markets can confidently make notified decisions based on dependable and credible outcomes.

Non-Destructive Examining Methods

Non-destructive testing strategies play a vital duty in making certain the integrity of sophisticated materials by enabling accurate assessment without creating damage. These techniques are necessary in sectors that rely upon the performance of products such as aerospace, automobile, and building.

One of one of the most common non-destructive screening methods is Visual Assessment, which entails checking the surface of a material for problems, such as splits, rust, or delamination. This strategy is easy and cost-efficient, making it a popular selection in lots of industries.

One more commonly used technique is Ultrasonic Screening (UT), which makes use of high-frequency sound waves to discover internal problems or disparities in products. By analyzing the representation of audio waves, UT can provide beneficial details about the thickness, stability, and density of a product. This method is especially effective for identifying hidden cracks or spaces in steels, composites, and various other products.

Magnetic Particle Testing (MT) is one more non-destructive strategy that is frequently used to identify surface area and near-surface defects in ferromagnetic materials. By using magnetic areas and magnetic bits to the product, MT can determine cracks, seams, and various other flaws that could endanger its structural honesty.

Advanced Analytical Instruments

Utilizing advanced technology, progressed analytical tools supply specific evaluation of materials for reputable outcomes. These tools play a vital duty in products screening, enabling scientists and designers to obtain a deeper understanding of the make-up, framework, and residential or commercial properties of numerous materials.

An additional crucial tool is the X-ray diffractometer (XRD) XRD enables scientists to evaluate the crystal structure of materials by determining the diffraction pattern of X-rays that engage with the sample. This technique provides info concerning the plan of atoms within the material, assisting to identify phases, crystallographic issues, and grain positionings.

Moreover, advanced logical instruments additionally consist of Fourier-transform infrared spectroscopy (FTIR), which analyzes the communication in between infrared radiation and a material to recognize its chemical structure and practical teams. Furthermore, strategies such as atomic pressure microscopy (AFM) and energy-dispersive X-ray spectroscopy (EDS) are employed to examine surface topography and essential structure, specifically.

High-Temperature Testing Solutions

To attend to the challenges of materials checking at high temperatures, specialized options have actually been developed to guarantee reliable and exact outcomes. High-temperature testing is crucial in various industries, such as aerospace, automobile, and power, where products should stand up to severe conditions. These solutions include making use of innovative tools and strategies that can take care of and simulate severe temperatures.

Another crucial element of high-temperature testing services is the development of advanced dimension and evaluation methods. These methods allow researchers to accurately monitor and track the behavior of products under extreme temperature levels. Non-contact dimension techniques, such as thermal imaging and spectroscopy, are frequently utilized to evaluate thermal conductivity, expansion, and other important material homes.

Furthermore, high-temperature testing options commonly entail the usage of sophisticated products, such as refractory metals and porcelains, that can withstand severe warmth without compromising their structural honesty. These products are used in the construction of fixtures, sensors, and various other components necessary for precise screening.

Advanced Mechanical Evaluating Techniques

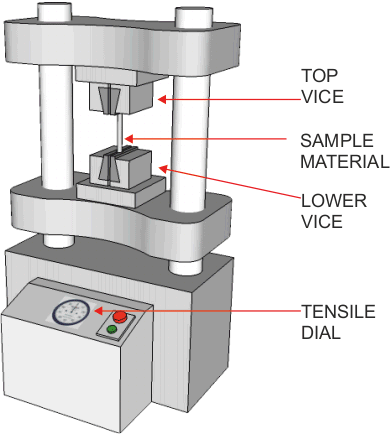

One generally made use of mechanical screening technique is tensile screening, which check my source applies a regulated pressure to a product sample to measure its ability to hold up against stress. This test aids identify crucial mechanical homes such as ductility, toughness, and elasticity.

Another innovative mechanical testing technique is firmness screening, which measures a product's resistance to impression or infiltration. This examination is important for assessing a material's capability to stand up to wear, deformation, and crack.

Additionally, exhaustion screening is utilized to examine a product's resistance to repeated loading, replicating real-life problems official source where elements experience cyclic stress and anxieties. This examination is specifically vital for sectors such as aerospace and auto, where the integrity and resilience of materials are important.

Along with these techniques, advanced mechanical testing consists of effect testing, creep testing, and crack durability testing, to name a few. These approaches give beneficial understandings into a material's actions under various mechanical conditions and aid ensure the reliability and safety and security of numerous applications.

Customized Testing Solutions

Personalized screening remedies are tailored to satisfy certain needs and offer reputable and exact outcomes in products screening. There is no one-size-fits-all strategy when it comes to screening products. Each product has one-of-a-kind residential properties and characteristics that require customized screening approaches. Personalized screening options ensure that these certain requirements are met, allowing for trusted and exact results.

Among the major advantages of tailored screening options is their adaptability. They can be developed to fit a wide variety of materials, consisting of metals, porcelains, polymers, and compounds. By recognizing the distinct properties of each product, testing specifications can be maximized to guarantee reliable and exact results.

An additional benefit of customized testing options is their ability to resolve specific testing demands. Whether it is testing the continue reading this mechanical residential or commercial properties, exhaustion actions, or thermal security of a product, a personalized technique can be established to fulfill these demands. This makes certain that the screening procedure is efficient and effective, saving time and resources.

Customized testing solutions additionally supply the benefit of flexibility. As new materials and testing needs arise, these options can be customized and updated to accommodate the changes. This makes certain that the screening process remains updated and appropriate in an ever-evolving market.

Conclusion

To conclude, progressed materials examining options provide trustworthy results via non-destructive screening techniques, progressed analytical instruments, high-temperature screening solutions, advanced mechanical testing approaches, and personalized testing services. These methods and instruments play an essential function in ensuring the high quality and performance of materials in numerous markets. Using these sophisticated screening techniques can boost the understanding, characterization, and optimization of materials, bring about enhanced item development and general efficiency.

With the ever-increasing intricacy of innovative materials, it is critical to depend on durable and dependable screening remedies (materials test lab). High-temperature testing options enable the evaluation of materials' efficiency under severe problems

Customized testing remedies are tailored to meet certain needs and provide trustworthy and accurate results in materials screening.An additional advantage of personalized screening remedies is their ability to deal with certain screening demands.In conclusion, advanced materials evaluating services use reliable results with non-destructive screening strategies, advanced analytical tools, high-temperature testing remedies, advanced mechanical testing methods, and personalized screening options.